-

Aircraft & Spacecraft

Aircraft & Spacecraft -

Heat Exchangers

Heat Exchangers -

Pipelines

Pipelines -

Tubes

Tubes -

Turbines

Turbines -

Bolts and threads

Bolts and threads -

Vessels

Vessels -

Offshore

Offshore -

Ships

Ships -

Railroad

Railroad -

Tanks

Tanks -

View All

View All

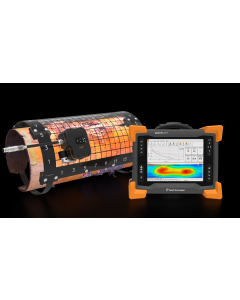

- Panther™ 2 256:256, PAUT UT TOFD TFM256. x2 128-units

SKU# PANTHER2-256:256PR-TFM

Price:USD 224,730.00